Learn Something New about 3D Printers

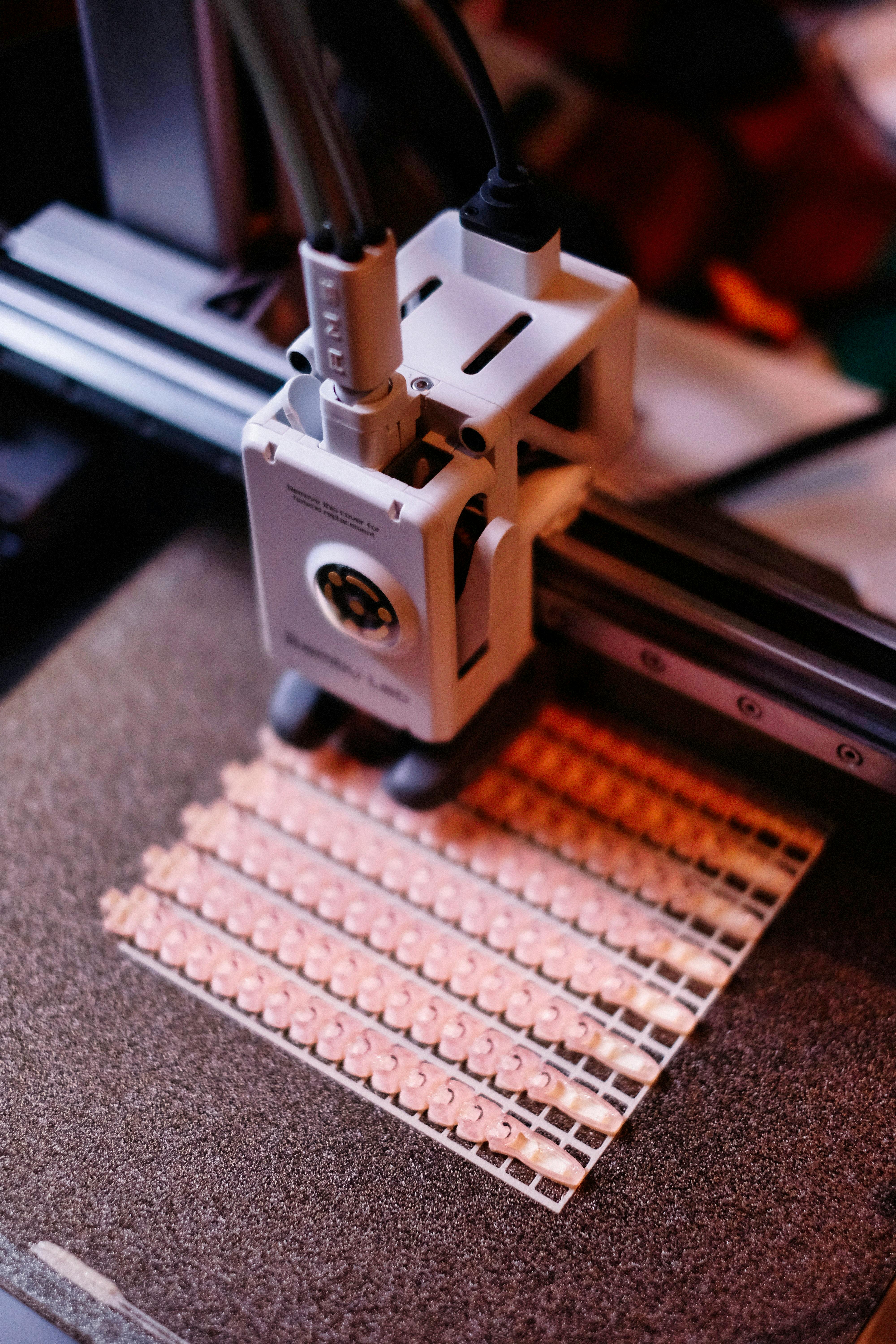

Three-dimensional printing technology has revolutionized manufacturing and creative industries, transforming digital designs into physical objects layer by layer. From hobbyist workshops to industrial production lines, these machines offer unprecedented possibilities for prototyping, customization, and small-scale manufacturing. Understanding the fundamentals of 3D printing opens doors to innovation across multiple fields, whether you're exploring creative projects or professional applications.

3D printing has moved from a niche workshop tool to a practical option for homes, schools, makers, and small businesses across the UK. Understanding the differences between machine types, the features that affect print quality, and the capabilities that define professional systems helps you match a printer to your specific goals. Below, you will find clear guidance, real-world cost pointers, and a straightforward comparison to ground your decision.

What Makes the Best 3D Printers Stand Out

The best 3D printers stand out through a combination of reliability, motion control, and material handling. Rigid frames, quality linear rails or rods, and well-tuned firmware reduce vibration and ringing. Direct-drive extruders improve retraction and flexible filament performance, while all-metal hot ends extend temperature ranges for materials like PETG, ABS, and nylon. Automatic mesh bed levelling, filament runout sensors, and quiet 32-bit control boards reduce day-to-day friction. Ecosystem support also matters: well-maintained slicers, profiles for popular filaments, and an active UK community make setup faster and results more predictable.

Finding an Affordable 3D Printer Without Compromising Quality

Finding an affordable 3D printer without compromising quality is achievable if you focus on fundamentals over extras. Look for stable motion systems, a flat heated bed, safe power electronics, and a proven user base. Open-source or widely supported firmware helps with updates, while readily available spare parts and UK-compatible power supplies add convenience. Read user reports about first-layer consistency and long prints, as these reveal practical reliability.

Real-world cost insights in the UK: entry-level FDM printers commonly range from about £150 to £350, midrange enthusiast machines from roughly £400 to £900, and prosumer to professional FDM systems from £1,500 upward. Resin printers can start near £150 to £600 for consumer MSLA units, with professional resin machines running into several thousand pounds. Ongoing costs include filament at around £15–£30 per kg for PLA and PETG, speciality filaments at higher prices, and resin typically £25–£70 per litre. Factor in nozzles, build plates, IPA or water-based cleaning for resin, filters, and occasional spares. Prices are estimates and vary by seller and availability.

Choosing a 3D Printer for Beginners

Choosing a 3D printer for beginners often comes down to safety, setup ease, and support. FDM models with assisted or automatic bed levelling, direct-drive extruders, pre-tuned slicer profiles, and clear on-printer guidance reduce the learning curve. Look for enclosed designs if you plan to print ABS to help manage fumes and warping, and ensure the machine uses UK-compliant plugs and has clear safety documentation. Beginner-friendly software with one-click profiles is valuable; well-known slicers provide sensible defaults, making it easier to learn how layer height, speeds, and temperatures influence output. For households and classrooms, low-odour filaments like PLA and good ventilation are practical considerations.

Professional 3D Printing Machine Capabilities

Professional 3D printing machine capabilities emphasise consistency, throughput, and material range. Features can include dual or independent extrusion for soluble supports, hardened nozzles for fibre-reinforced filaments, and enclosed, heated build chambers to manage engineering polymers. Networked fleet management, job queuing, and remote monitoring are common in professional environments, as are quality-of-life features like filament drying, automatic calibration routines, and detailed error recovery. Documentation, service agreements, and validated material profiles matter when repeatability is required, whether for jigs, fixtures, or short-run functional parts. Consider noise levels, ventilation requirements, and office compatibility when evaluating machines for shared spaces.

High Resolution 3D Printer Technology

High resolution 3D printer technology depends on the way each process forms layers. In FDM, fine nozzles and tuned motion control improve detail, while linear advance, input shaping, and better flow calibration enhance corners and surfaces. Resin printers determine XY detail by LCD pixel size or a laser’s spot size, often yielding sharper features for miniatures and dental models. Anti-aliasing algorithms and monochrome LCDs can reduce cure times while preserving detail. Remember that resolution is only one part of quality; dimensional accuracy also depends on calibration, part orientation, supports, and material properties.

UK pricing and comparisons

Below is a snapshot of commonly referenced machines available through UK channels. It covers a spread from budget to professional, to illustrate realistic price bands and providers.

| Product/Service | Provider | Cost Estimation |

|---|---|---|

| Ender 3 V3 SE (FDM) | Creality | £180–£230 |

| Kobra 2 (FDM) | Anycubic | £200–£280 |

| P1S (FDM) | Bambu Lab | £699–£849 |

| MK4 (FDM) | Prusa Research | £949–£1,099 |

| Mars 4 (Resin) | Elegoo | £180–£250 |

| Form 3+ (Resin) | Formlabs | £3,300–£4,200 |

| S3 (FDM) | Ultimaker | £3,300–£4,000 |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

In practice, UK street prices fluctuate with promotions, VAT-inclusive listings, and stock levels. When comparing, confirm what is included in the box, such as nozzles, build plates, and starter materials, and check warranty terms and local service options in your area.

Conclusion

Selecting a 3D printer is ultimately about matching capabilities to needs. Prioritise frame rigidity, motion control, and software support for consistent results, weigh the trade-offs between FDM and resin for your parts, and budget for consumables alongside the machine price. With a clear view of features, realistic UK costs, and how resolution and materials affect outcomes, you can make an informed choice for home, classroom, or professional use.