Pioneering the Industrial Landscape: The Ascendancy of Additive Manufacturing

While the industrial sector has seen numerous advancements over the years, additive manufacturing, commonly known as 3D printing, is emerging as a game changer. This technology's introduction has paved the way for unparalleled levels of customization and on-demand production, revolutionizing traditional manufacturing methodologies.

Historical Journey: From Concept to Reality

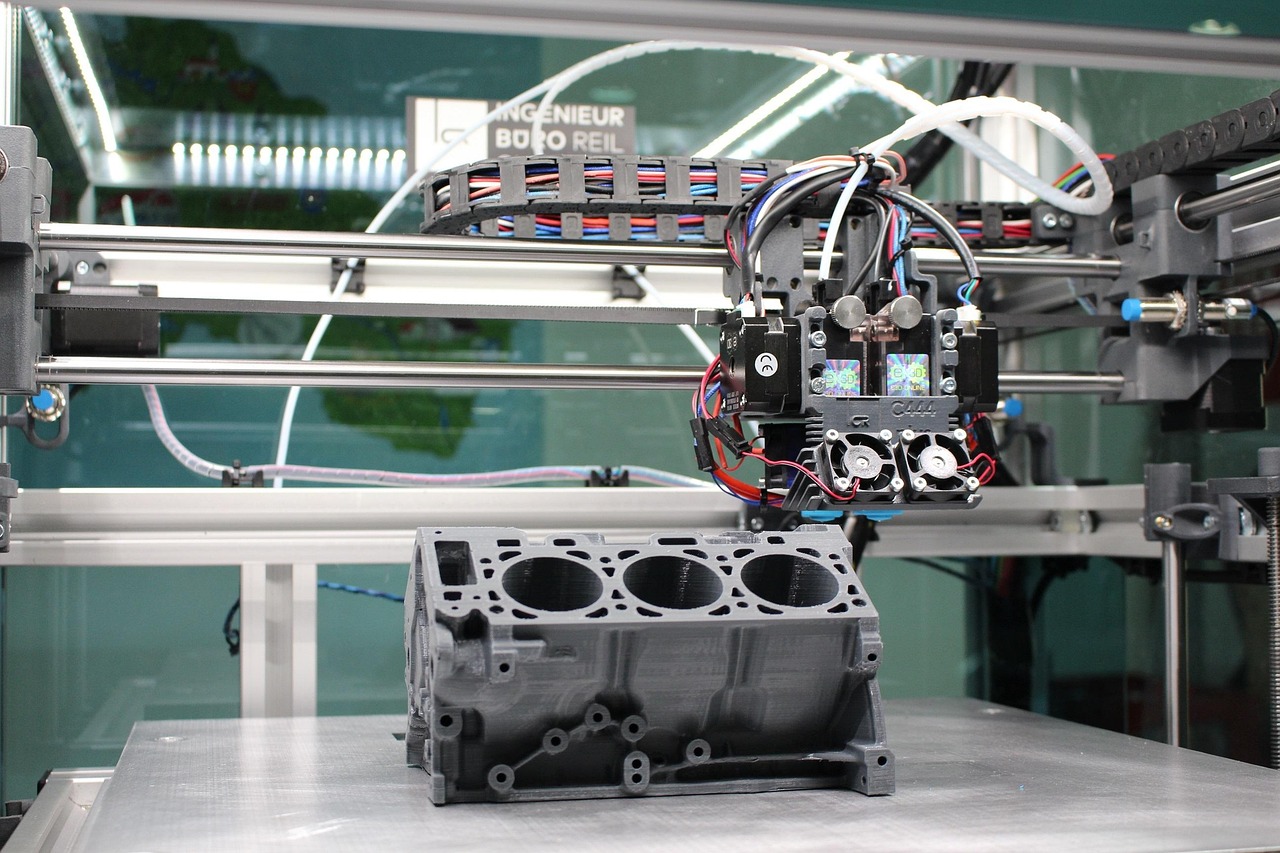

Originating in the 1980s, additive manufacturing was initially utilized for rapid prototyping. However, its capabilities have expanded over the years, evolving into a versatile manufacturing method. It has shifted from creating simple plastic models to producing sophisticated components for aerospace, medical, and automotive industries.

Current Trends: The Dawn of a New Era

The adoption of additive manufacturing is on the rise. According to a report by SmarTech, the global market for this technology is expected to reach $35.6 billion by 2024. Key drivers include the demand for cost-effective production, the need for complex geometrical designs, and the desire for waste reduction.

The Impact of Additive Manufacturing: A Double-Edged Sword

While additive manufacturing offers numerous benefits, such as reduced waste, increased speed, and greater customization, it also presents unique challenges. These include the need for specialized materials, skilled workforce, and potential intellectual property issues. However, the benefits far outweigh the drawbacks, making it an attractive option for industries seeking to innovate and customize their offerings.

Future Outlook: Riding the Wave of Innovation

The future of additive manufacturing looks promising, with potential applications in diverse sectors, such as healthcare, construction, and food production. As the technology matures and becomes more accessible, it is set to redefine the boundaries of traditional manufacturing.

Practical Insights: Harnessing the Potential of Additive Manufacturing

- Invest in Training: As additive manufacturing requires specialized skills, investing in workforce training is crucial.

- Embrace Innovation: Don’t shy away from exploring innovative designs and applications for this technology.

- Partner Smartly: Collaborate with technology providers and industry experts to ensure smooth integration into your operations.

- Prioritize Quality: While speed and cost-efficiency are important, maintaining high-quality standards is vital.

In conclusion, additive manufacturing is poised to transform the industrial landscape with its versatility, efficiency, and innovation potential. By understanding its history, recognizing current trends, and considering its impact, businesses can make informed decisions and leverage this technology for competitive advantage. As with any new technology, challenges exist, but the opportunities far outweigh them, marking additive manufacturing as a key player in the future of industrial operations.