Pioneering Productivity: Understanding the Impact of Industrial Automation

Introduction: Industrial automation is no longer the stuff of science fiction, but a practical reality shifting the gears of productivity in the industrial sector. Let's delve into this transformative technology, and how it's reshaping the modern business and industrial landscape.

Industrial Automation: A Historical Overview

Industrial automation, in its broadest sense, refers to the use of systems or machines that have the capability to operate without human intervention. The roots of automation trace back to the 19th century with the invention of automated machinery for the textile industry. The concept has evolved significantly over time, with the advent of computers and robotics in the 20th century driving a massive acceleration in the adoption of automation technologies.

The Current Landscape of Industrial Automation

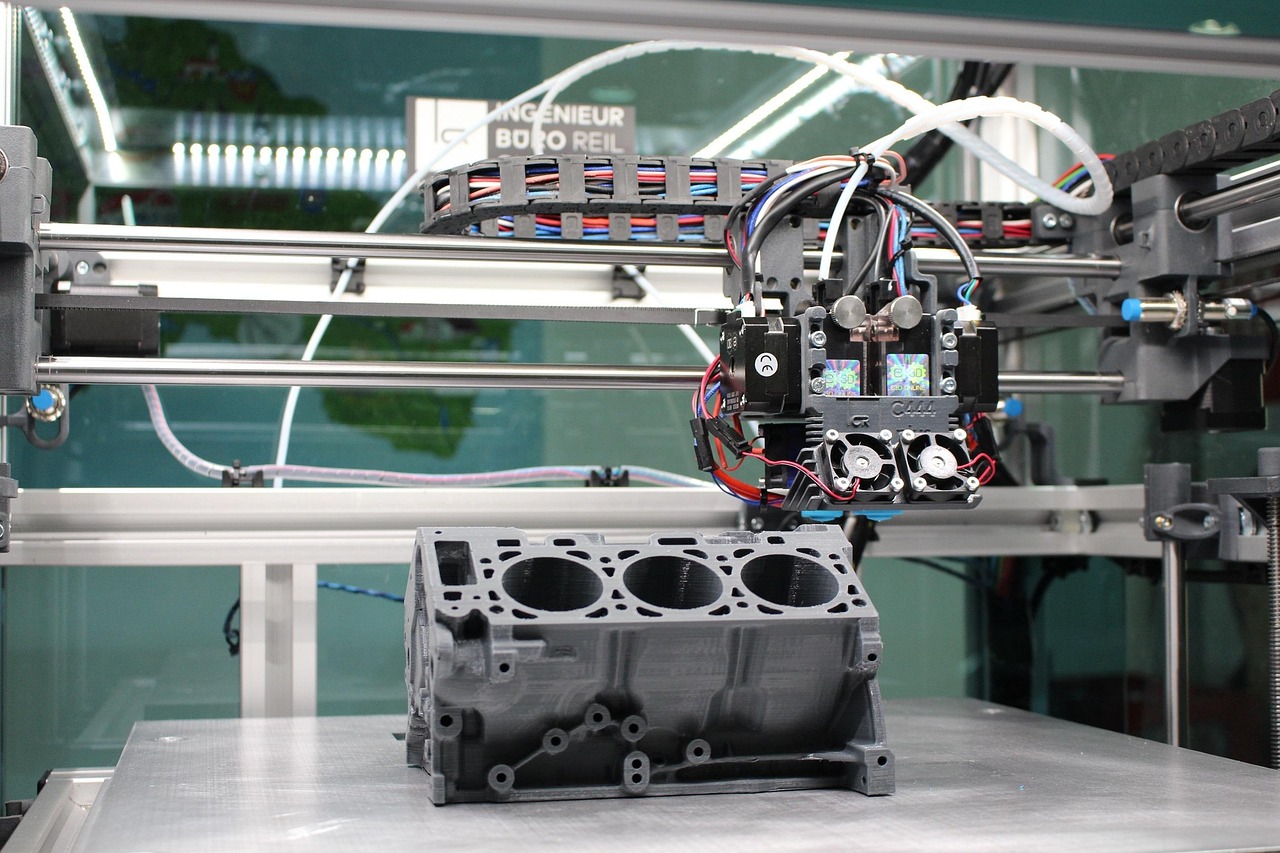

Today, industrial automation is a critical pillar of modern manufacturing and production processes. From automotive assembly lines to pharmaceutical manufacturing, automation technologies are enabling unprecedented levels of precision, efficiency, and scale. Particularly in the era of Industry 4.0, automation is not just about replacing manual labor with machines - it’s about integrating smart, connected systems that can enhance productivity, improve quality, and reduce costs.

The Implications of Industrial Automation

Industrial automation presents a range of benefits, such as increased production speed, reduced human error, and enhanced safety in hazardous working conditions. However, it also poses challenges, including the potential displacement of certain job roles and the need for significant upfront investment. Moreover, as automation technologies become more sophisticated, issues such as cybersecurity and data privacy are emerging as critical considerations.

The Future of Industrial Automation: A Research Perspective

According to multiple research reports, the industrial automation market is projected to continue growing at a robust pace. The rise of technologies like machine learning, artificial intelligence, and the Internet of Things (IoT) is expected to further push the boundaries of what’s possible with automation. However, to fully realize the potential of these technologies, businesses must also invest in upskilling their workforce and developing robust cybersecurity measures.

Unleashing the Potential of Industrial Automation

- Invest in employee education and training to ensure your workforce possesses the skills to work alongside automation technologies.

- Prioritize safety and security. This includes both physical safety measures for automated machinery and cybersecurity measures for digital systems.

- Start small and scale up. Rather than adopting a complete automation overhaul, consider starting with one or two processes and expanding as you learn and adapt.

- Stay abreast of the latest trends and developments in automation technologies to ensure your business stays competitive.

Concluding Thoughts

Industrial automation is a powerful tool in the quest for increased productivity and efficiency. However, like any tool, its success depends on how effectively it’s used. By understanding the history, current trends, and future directions of automation, businesses can make informed decisions that drive growth and competitiveness in the ever-evolving industrial sector. Through strategic implementation and ongoing adaptation, industrial automation can become a cornerstone of sustainable, future-focused business and industrial operations.